A variety of procedures and systems are used in milking methods and practices to effectively extract milk from dairy animals while maintaining the animals’ well-being and the milk’s quality. Traditional hand milking and contemporary machine milking are among these techniques; additional variations include robotic systems, bucket, pipeline, and parlor milking. The right preparation of the cow, regular milking techniques, post-milking care, strict hygiene, and quality control measures are important practices. Dairy farmers can maximize milk production and guarantee high standards of milk quality by implementing cutting-edge technology, upholding animal welfare, and following sustainable practices.

Table of Contents

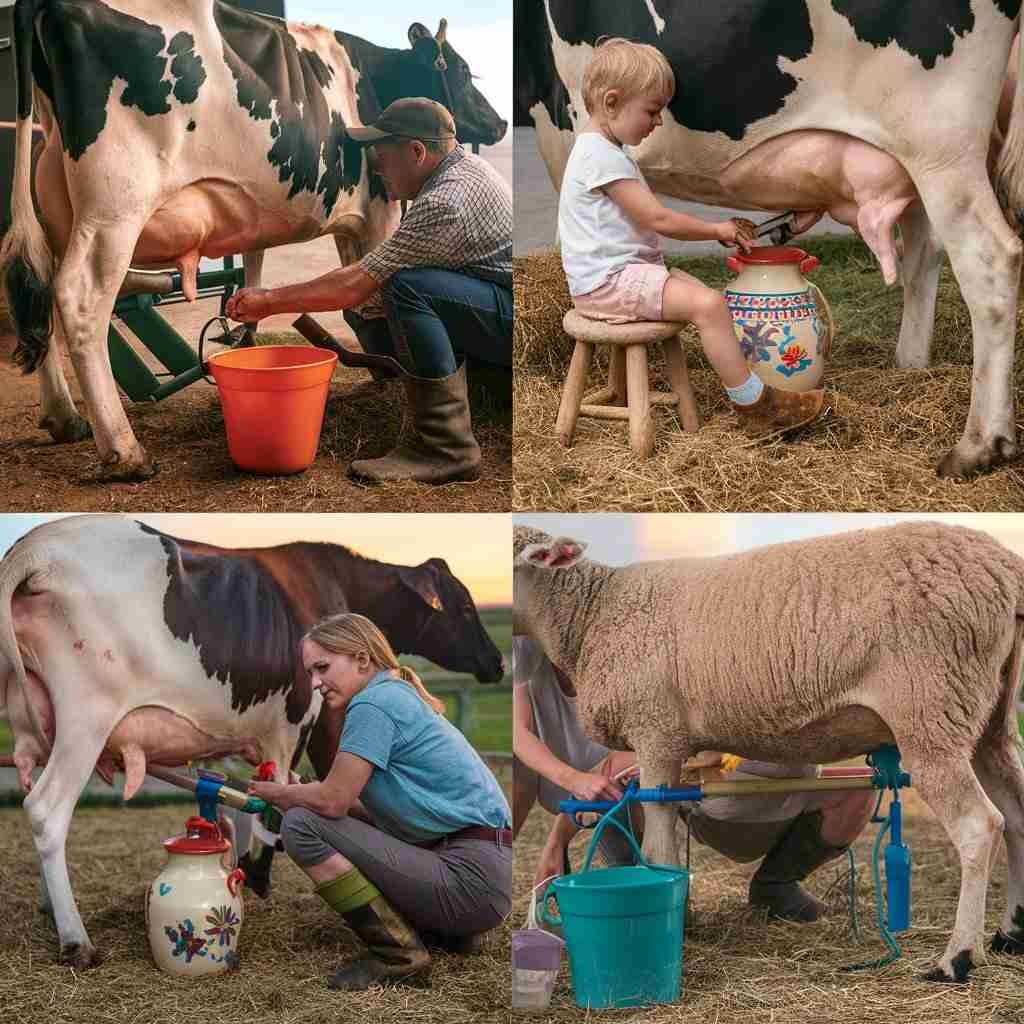

Introduction to Milking methods and practices

Milking methods and practices are the procedures and systems used to effectively and hygienically extract milk from dairy animals. The manual milking techniques that are still used today include bucket, pipeline, parlor, and robotic systems, among other machine-assisted techniques. Preparing the cow, milking her consistently and gently, taking care of her afterward, and maintaining stringent standards of hygiene and quality control are all components of efficient milking practices. Ensuring animal health and welfare, maintaining high standards for milk quality, and optimizing milk production are the objectives.

Milking Methods

The different types of milking methods are described below:

1. Hand Milking:

This traditional milking methods involves manually extracting milk from the animal’s udder. There are two primary techniques:

- Stripping: The milker grasps each teat individually, applying gentle pressure and a downward motion to express the milk. This milking methods requires practice to ensure complete milking without harming the teat.

- Full Hand Milking: The milker encloses the entire teat and udder base with both hands, applying rhythmic compression to stimulate milk letdown and promote complete milking. It’s considered gentler on the udder compared to stripping.

2. Machine Milking:

This is the dominant milking methods in modern dairy farming due to its efficiency and scalability for large herds. Here’s how it works:

- Milking Machine: The core component is a milking unit with teat cups that fit snugly over each teat. A pulsating vacuum system creates a gentle suction, mimicking a calf’s suckling action and drawing milk out.

- Milking Process: The udder is prepared by cleaning and stimulating the teats to trigger milk letdown. The milking unit is attached, and the machine automatically cycles between milking and rest phases to ensure optimal milk flow and teat health.

Types of Milking Systems

The types of milking systems are presented below:

1. Bucket Milking Systems

- Description: A bucket that is fastened to the milking machine is used to collect milk.

- Benefits: Transportable and appropriate for small herds.

- Drawbacks: Buckets must be cleaned and emptied frequently.

2. Pipeline Milking Systems

- Description: Milk is sent straight from the milking machines to a bulk tank via a network of pipes.

- Benefits: Less milk handling, appropriate for larger operations, and efficient.

- Drawbacks: More expensive initially, needs careful installation and upkeep.

3. Parlor Milking Systems

- Description: Specialized structures with a range of configurations (e.g., herringbone, parallel, rotary) where cows are brought for milking.

- Benefits: Great productivity, ergonomics for employees, and capacity for more extensive herd management.

- Drawbacks: High initial outlay and expert operation required.

4. Robotic Milking Systems

- Description: Automatic systems in which the machine automatically attaches itself to the teats when the cows willingly enter the milking unit.

- Benefits: Saves labor, allows for multiple milkings per day, and gathers comprehensive information on every cow.

- Drawbacks: Expensive upfront costs, need for technical expertise for upkeep and operation.

Milking Practices

Some of the milking practices are described below:

1. Preparation of Cows

- Cleanliness: To avoid contamination, make sure the udders and teats are clean.

- Stimulation: Practices prior to milking, such as massaging the udder, to encourage the release of milk.

2. Milking Procedure

- Consistency: To maximize milk production, stick to a regular milking schedule.

- Gentleness: To prevent stress and injury, handle teats with gentleness.

3. Post-Milking Care

- Teat Disinfection: To avoid infections, use teat dips after milking.

- Health Monitoring: Keep an eye out for any indications of mastitis or other health problems with the udder.

Hygiene and Quality Control

1. Equipment Cleaning

- Regular Cleaning: To stop bacterial growth, clean bulk tanks, pipelines, and milking machines after every milking session.

- Sanitization: Make sure to clean thoroughly by using the right sanitizers.

2. Milk Storage

- Cooling: In order to maintain quality and stop bacterial growth, quickly cool milk to 3–4°C.

- Storage Tanks: Before milk is transported, store it in stainless steel bulk tanks.

3. Milk Testing

- Regular Testing: To guarantee quality, test milk for antibiotic residues, bacterial count, and somatic cell count (SCC).

- Keeping Records: Keep thorough records of milk production and quality assessments.

Animal Health and Welfare

1. Nutrition and Feeding

- Balanced Diet: To guarantee the best possible milk production and animal health, provide a balanced diet.

- Water Access: Make certain you always have access to pure water.

2. Comfort and Housing

- Clean Environment: To avoid infections, keep living spaces dry and clean.

- Comfortable Bedding: To prevent stress and injuries, use the right bedding.

3. Health Monitoring

- Regular Checks: Keep an eye on your health to identify and address problems early.

- Vaccinations: Stay current on immunizations and preventive medical care.

Technology and Innovation

1. Data Management Systems

- Tracking: Make use of software to monitor feeding schedules, milk production, and cow health.

- Analysis: To maximize milking procedures and boost productivity, analyze data.

2. Sensor Technology

- Use: In real time, sensors can track milk output, cow health, and milk quality.

- Benefits: Offers information for improved herd management and early health problem identification.

3. Genetic Selection

- Use: Breeding and choosing animals with features associated with high milk production.

- Benefits: Over time, improves milk output and the general quality of the herd.

For a dairy business to be successful, using the appropriate milking methods and best practices is essential. To produce high-quality milk and guarantee the wellbeing and productivity of dairy cows, strict hygienic practices, animal welfare, and efficiency requirements must be followed, whether employing sophisticated robotic systems or manual milking techniques.

Frequently Asked Question(FAQ)

What are the main methods of milking?

Hand Milking: A traditional method using manual hand pressure.

Machine Milking: Utilizes mechanical milking machines for efficiency.

Automatic Milking Systems (AMS): Also known as robotic milking, allowing cows to milk themselves at their convenience.

What is the importance of hygiene in milking?

Maintaining good hygiene is essential to avoiding illnesses in cows and contaminating milk. This entails sterilizing equipment after every use and washing the udder prior to milking.

Related Articles