An Internal Combustion Engine (IC Engine) is a machine in which fuel combustion takes place within the engine, producing heat that is transformed into mechanical power. IC engines are commonly utilised in automobiles, tractors, and motorbikes. They occur in a variety of forms and configurations, depending on their design and use.

Table of Contents

Engine Types

- Two-Stroke Engines:

- Operation: In a two-stroke engine, the entire combustion cycle (intake, compression, combustion, and exhaust) is completed in two piston strokes, i.e., one revolution of the crankshaft.

- Applications: Typically used in smaller machines like motorcycles, scooters, chainsaws, and some small power equipment.

- Advantages: Lighter, simpler in design, and higher power-to-weight ratio.

- Disadvantages: Less fuel-efficient, higher emissions, and increased wear due to shorter lubrication intervals.

- Four-Stroke Engines:

- Operation: A four-stroke engine completes the combustion cycle in four strokes of the piston (intake, compression, power, and exhaust) over two revolutions of the crankshaft.

- Applications: Commonly used in cars, trucks, tractors, and larger machinery.

- Advantages: More fuel-efficient, cleaner emissions, and longer-lasting due to better lubrication.

- Disadvantages: Heavier, more complex, and higher production cost compared to two-stroke engines.

Principles of Operation

- Two-Stroke Cycle Engines (Compression Ignition & Spark Ignition):

- Compression Ignition (Diesel Engines):

- Principle: Air is compressed to a high pressure and temperature, and fuel (diesel) is injected into the hot air, causing it to combust.

- Process:

- First Stroke (Compression): The air-fuel mixture is compressed.

- Second Stroke (Power): Combustion occurs, and the exhaust is released.

- Spark Ignition (Petrol Engines):

- Principle: A fuel-air mixture is compressed and ignited by a spark from a spark plug.

- Process:

- First Stroke (Compression): The air-fuel mixture is compressed.

- Second Stroke (Power): A spark ignites the mixture, and the piston is pushed downward.

- Compression Ignition (Diesel Engines):

- Four-Stroke Cycle Engines (Compression Ignition & Spark Ignition):

- Compression Ignition (Diesel Engines):

- Principle: Similar to the two-stroke diesel engine, but with a distinct four-step process.

- Process:

- Intake Stroke: Air is drawn into the cylinder.

- Compression Stroke: Air is compressed, raising its temperature.

- Power Stroke: Fuel is injected into the compressed air, igniting it and causing combustion.

- Exhaust Stroke: Exhaust gases are expelled from the cylinder.

- Spark Ignition (Petrol Engines):

- Principle: A mixture of air and fuel is compressed and ignited by a spark plug.

- Process:

- Intake Stroke: The air-fuel mixture enters the cylinder.

- Compression Stroke: The mixture is compressed.

- Power Stroke: A spark ignites the mixture, causing combustion and driving the piston.

- Exhaust Stroke: The exhaust gases are expelled.

- Compression Ignition (Diesel Engines):

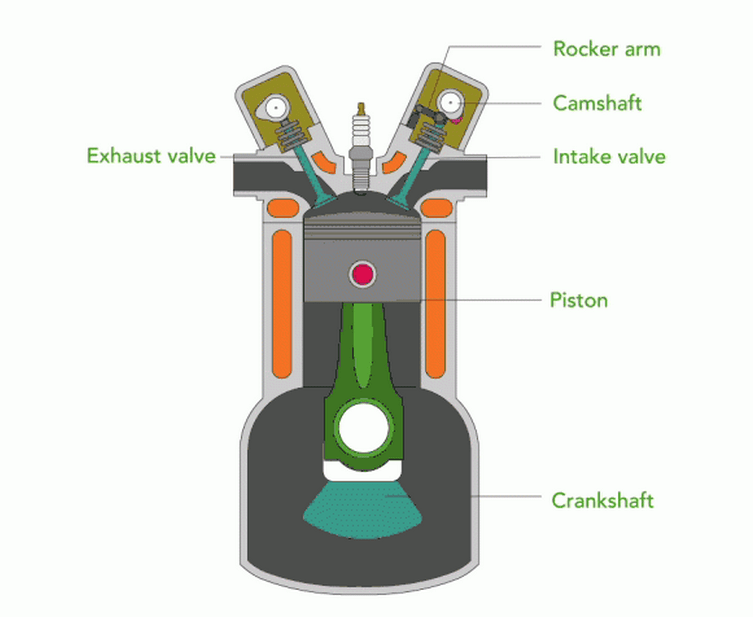

Components of Internal Combustion Engines and Their Functions

- Cylinder Block: The engine’s main body that houses the cylinders, where combustion occurs.

- Cylinder Head: Seals the top of the cylinders and contains the combustion chamber, valves, and spark plug (in petrol engines) or fuel injector (in diesel engines).

- Piston: Moves up and down inside the cylinder, transmitting the force of combustion to the crankshaft.

- Crankshaft: Converts the reciprocating motion of the piston into rotational motion.

- Camshaft: Operates the intake and exhaust valves, controlling the engine’s breathing.

- Connecting Rod: Connects the piston to the crankshaft and transmits motion.

- Flywheel: Stores rotational energy to smooth out the crankshaft’s rotation.

- Valves (Intake & Exhaust): Control the flow of air/fuel mixture into and out of the cylinder.

- Spark Plug (in petrol engines): Produces the spark to ignite the air-fuel mixture.

- Fuel Injector (in diesel engines): Injects diesel fuel into the cylinder.

Systems in Two-Wheel and Four-Wheel Tractor Engines

- Fuel Supply System:

- Petrol Engines:

- Components: Fuel tank, fuel pump, carburetor (or fuel injector), and fuel lines.

- Function: Delivers the correct mixture of fuel and air to the combustion chamber.

- Diesel Engines:

- Components: Fuel tank, fuel pump, fuel injector, and fuel filter.

- Function: Pressurizes and injects fuel directly into the combustion chamber.

- Petrol Engines:

- Air Cleaning System:

- Components: Air filter, intake manifold.

- Function: Cleans the air entering the engine to remove dust and debris, preventing engine wear.

- Types: Oil bath filters or dry paper filters, depending on the engine design.

- Cooling System:

- Components: Radiator, water pump, thermostat, and coolant.

- Function: Removes excess heat from the engine to prevent overheating.

- Types:

- Liquid Cooling: Uses a coolant to transfer heat from the engine to the radiator, where it is dissipated.

- Air Cooling: Uses airflow over the engine to dissipate heat (commonly used in smaller engines).

- Lubrication System:

- Components: Oil pump, oil filter, and oil pan.

- Function: Reduces friction between moving parts by supplying oil to critical areas, preventing wear and tear.

- Types:

- Splash Lubrication: Oil is splashed onto the moving parts.

- Pressure Lubrication: An oil pump circulates oil to all parts of the engine under pressure.

Key Differences between Two-Wheel and Four-Wheel Tractor Engines

- Two-Wheel Tractors:

- Usually small, lightweight, and are powered by a smaller engine (often single-cylinder diesel or petrol engines).

- Primarily used for small-scale farming, horticulture, and in areas with limited space.

- More affordable and fuel-efficient but with lower power output.

- Four-Wheel Tractors:

- Larger, heavier, and powered by multi-cylinder engines (typically diesel engines).

- Used in large-scale farming, with higher pulling capacity and power for heavy-duty tasks.

- More expensive but capable of handling a wide variety of agricultural equipment and tasks.

Understanding these systems and components is crucial for the effective operation and maintenance of tractor engines in agricultural settings, particularly in countries like Nepal where tractors are vital for farm mechanization.

Frequently Asked Questions (FAQs)

What are the 4 type of internal combustion engine?

Internal-combustion engines are the most extensively used power generation technology available today. Examples include gasoline and diesel engines, gas turbine engines, and rocket propulsion systems.

What is the principle of internal combustion engine?

IC engine converts chemical energy of the fuel into mechanical energy, usually made available on a rotating output shaft.

What is the classification of IC engine?

We can classify the engines based on their fuel types as gasoline, diesel, LPG, and CNG, and compare and contrast some of their basic characteristics.

Related Article