What is casing in mushroom farming?

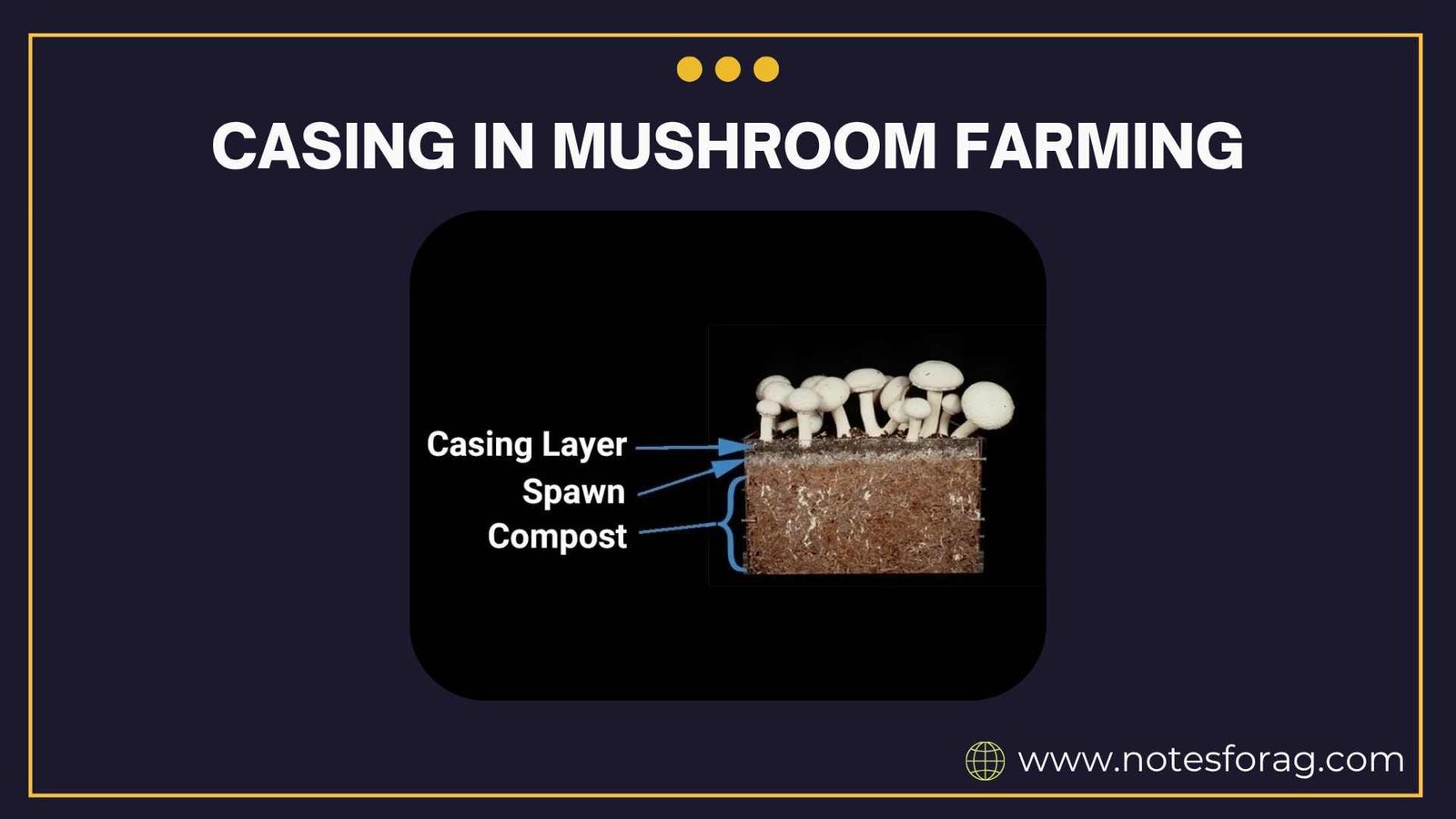

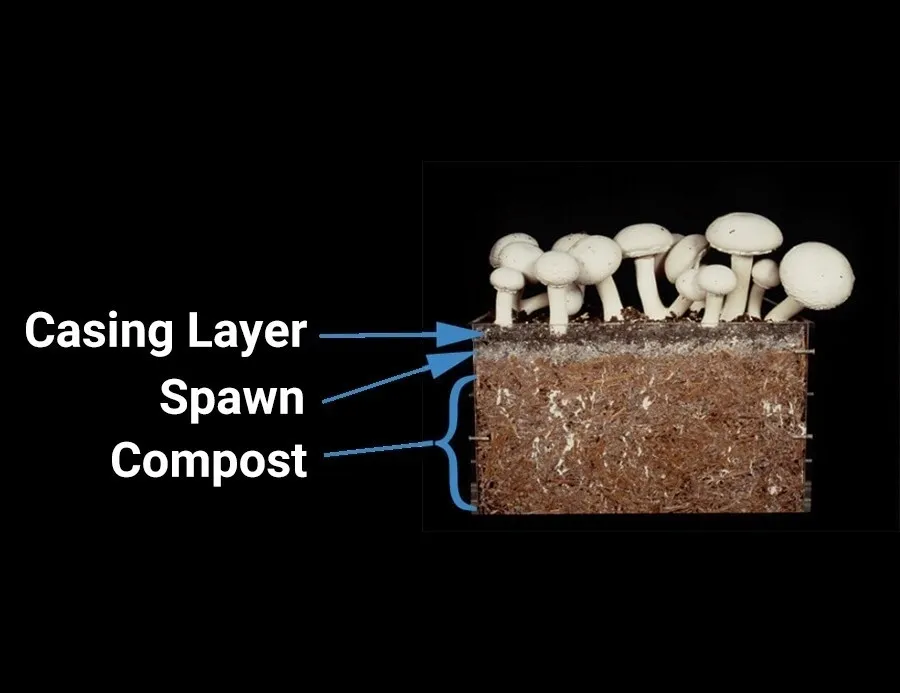

Casing in mushroom farming is an important step, especially in the cultivation of species like Agaricus bisporus (commonly known as the white button mushroom). After the mycelium has completely colonized the compost or substrate, a layer of casing material is applied on top. This casing layer does not serve as a source of nutrients, but rather plays a vital role in triggering mushroom formation and providing the right environment for fruit body development.

Summary of Casing in mushroom farming

- The Purpose of Casing, Casing provides a protective layer over the compost to retain moisture, regulate temperature, and support the formation of mushroom pins.

- The common materials like peat moss, coco coir, and loam soil are commonly used for casing, each offering unique benefits such as moisture retention and aeration.

- Application process, after the compost is fully colonized by mycelium, a 2–3 cm thick casing layer is applied, followed by careful management of humidity and temperature to encourage fruiting.

Table of Contents

Importance of casing in mushroom farming

Casing helps to maintain the right moisture levels, supports the exchange of gases, and provides a physical support structure for mushroom pinning and growth. It also protects the mycelium underneath and helps mushrooms grow uniformly.

Characteristics of good materials for Casing in mushroom farming

A good casing material must have the following characteristics:

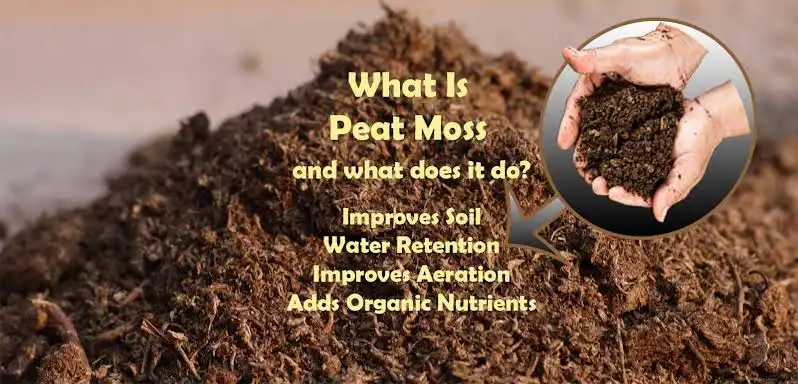

- High water-holding capacity: It should retain moisture effectively to supply the necessary humidity for mushroom development.

- Porosity: It should allow easy gas exchange and prevent waterlogging.

- Free of pathogens and pests: It should be clean and should not introduce contaminants into the mushroom bed.

- pH neutral to slightly alkaline: A pH around 7.0 to 8.0 is ideal.

- Easily available and cost-effective: It should be affordable and accessible to farmers.

Commonly used Casing materials

- Peat moss: This is the most commonly used casing material in commercial mushroom farming. It has excellent water-holding capacity and structure.

- Mixture of peat and lime: Lime is added to adjust the pH of peat moss.

- Farmyard manure and loam soil: Well-rotted manure mixed with loamy soil is sometimes used by small-scale farmers.

- Cocopeat: Derived from coconut husk, cocopeat is becoming increasingly popular due to its good moisture retention.

- Sand and soil mixtures: In some areas, a simple mixture of sand and soil is used, although it may not be as effective as peat-based mixtures.

Preparation of materials for Casing in mushroom farming

Before applying the casing material, it needs to be properly prepared to ensure cleanliness and effectiveness:

- Pasteurization or sterilization: The casing material must be free from harmful microbes. This can be done by pasteurizing it with steam or sterilizing it using chemicals like formalin.

- Moisture adjustment: The material should be moist but not dripping wet. A simple test is to squeeze the material in your hand it should feel damp but no water should drip.

- pH adjustment: If the pH is too acidic, lime is added to bring it to a neutral or slightly alkaline range.

Applications of Casing in mushroom farming

- Timing: Casing is done after the substrate is fully colonized by the mushroom mycelium.

- Thickness: The casing layer should be about 3–4 cm thick.

- Uniform application: It should be evenly spread over the surface of the substrate.

- Watering: After casing, light watering is done to moisten the surface without disturbing the layer.

Maintenance after Casing

Once the casing is applied, the mushroom bed requires careful monitoring:

- Humidity: Maintain high humidity (85–90%) to promote mushroom pinhead formation.

- Temperature: Keep optimal temperatures as per the mushroom species (e.g., 23–25°C for button mushrooms).

- Ventilation: Ensure good air circulation to prevent the build-up of carbon dioxide.

- Watering: Light and regular watering is done to keep the casing layer moist.

Role in Mushroom Production

Casing plays a major role in the success of mushroom production:

- It provides the right microclimate for pinning.

- It helps in the even formation of mushrooms.

- It extends the cropping period by holding moisture.

- It reduces contamination by acting as a barrier.

Problems associated with Casing

If the casing is not done properly, several problems can occur:

- Dry casing: Leads to poor mushroom formation.

- Contaminated casing: Can introduce molds and diseases.

- Improper pH: Affects the growth rate and yield.

- Compacted layer: Reduces air circulation, affecting mushroom formation.

Conclusion

Casing is a critical and technical step in mushroom farming. Though it does not feed the mushrooms directly, it creates the ideal environment for mushrooms to form and mature properly. Choosing the right casing material, preparing it carefully, and maintaining the right conditions after application are all essential for achieving high yields and quality produce. As mushroom farming continues to grow, improving casing techniques will help farmers become more successful and efficient in their production systems.

Frequently Asked Questions (FAQs)

What is casing in mushroom cultivation?

Casing is a thin layer of soil or soil-like material spread on top of the mushroom-growing bed (usually after the spawn run). It helps maintain moisture, supports mushroom growth, and encourages the formation of fruiting bodies.

What is casing in mushroom production?

In mushroom production, casing is the step where a moist, nutrient-free layer (like soil, compost, or peat moss) is added over the compost or substrate. It doesn’t feed the mushrooms but provides the right conditions for them to grow.

When is casing done in mushroom farming?

Casing is done after the spawn run is complete when the mushroom mycelium has fully colonized the substrate. This usually happens about 15–20 days after spawning, depending on the type of mushroom and conditions.

Related Articles